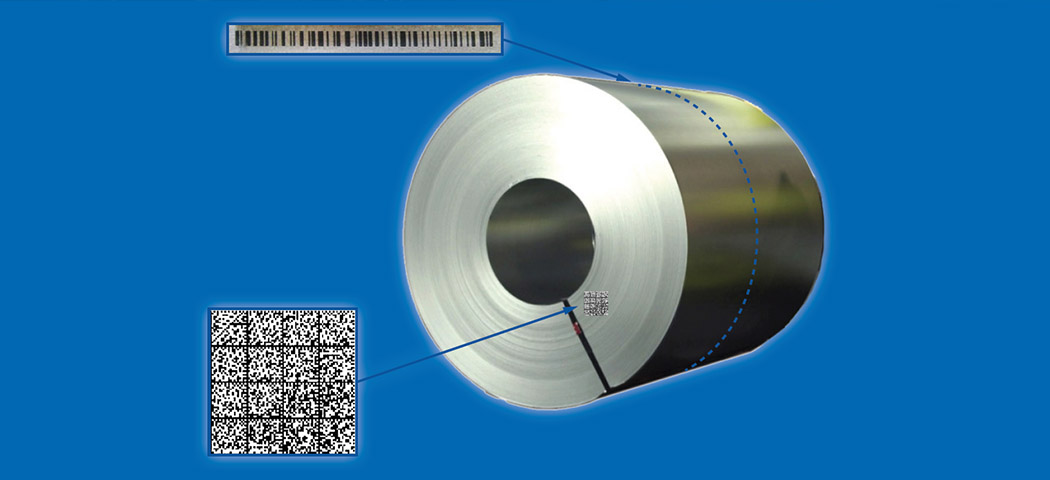

Barcode reading system for quality tracking solution of coils.

Steel coils - high-quality starting materials for high-quality products, especially in the automotive industry but also in the "white goods" sector with ever increasing quality requirements for manufacturers and processors. As part of a joint project, the three largest European steel producers ArcelorMittal, Tata Steel and ThyssenKrupp Steel Europe have developed an open concept for coding and passing on quality information to steel producers' customers. The concept has now been affiliated with EUROFER in Brussels for further coordination and dissemination, and other steel producers have joined the consortium.

The key to the whole concept is the printing and recognition of a 1D barcode on the coil to identify the location of additional quality information which is passed on to customers in coded form. This enables customers to selectively treat marked areas of the coil in further processing and thus reduce follow-up costs in processing and quality assurance while increasing the degree of utilization.

Barcode reading systems from OCTUM (CRS and BRS) are central elements of the quality tracking solution.

The barcode reading system from OCTUM (CRS = Customer Reading System and BRS = Barcode Reading System), which was specially developed for this application, fulfils the requirements of steel manufacturers and their customers for a reading system in harsh industrial environments as defined and documented in the "white book V2.2". The first generation of reading systems have been in use since 2012, the series devices that correspond to the current status of the white book have been delivered since 2015. The system reads the barcode on all steel surfaces with high reliability at speeds of up to 300m/min. The installations at steel manufacturers and their customers have confirmed the high reading rates >98% across all steel surfaces. In line installations at the steel manufacturers and freshly printed coils 100% detection rates were also achieved. Damage to the codes, additional printing between the 1D codes and variations in surface reflection do not interfere with detection. The reading system adapts automatically to the current conditions, manual intervention or parameterization is not necessary. Installation and operation of the barcode reading unit is simple.

The process coupling is defined and implemented differently depending on the application. Customer-specific adaptations beyond the white book are also possible at any time. For the installation in customer plants, a Quality Information Server is also necessary to provide the coded quality data in so-called Info Files. This component can also be provided directly by OCTUM.