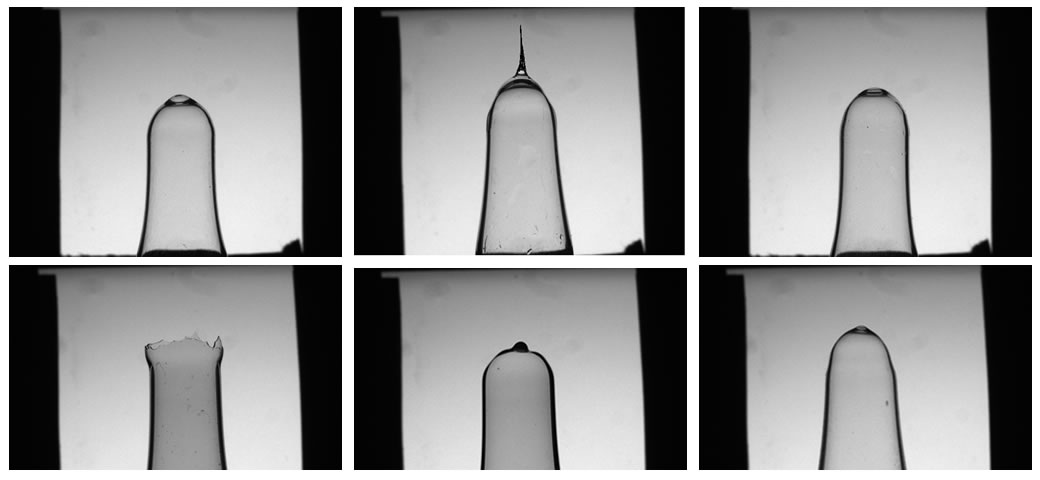

Flawless ampoules for beauty and health.

Higher quality requirements combined with faster production lines also place increased demands on the automatic inline inspection of the containers used, such as ampoules. It is essential to reliably detect both cosmetic and critical defects in the production cycle and to exclude non-conforming products from further use in the process.

The automatic inspection is usually carried out with intelligent camera systems in transmitted light arrangement at cycle rates of up to 36,000 pcs/h. The individual inspections can be parameterized according to customer specifications and can thus be easily adapted to a changed product spectrum. Likewise, the inspection sharpnesses can be adjusted to customer and product-specific requirements. The process coupling is done via all common standard interfaces, the direct process feedback ensures constant product quality. The complete system solution can be designed in compliance with GAMP 5. For the visualization the OCTUM system software OCTUMISEr is used which is installed on a stand-alone computer or integrated in the customer HMI. OCTUMISEr is also available as 21 CFR Part 11.