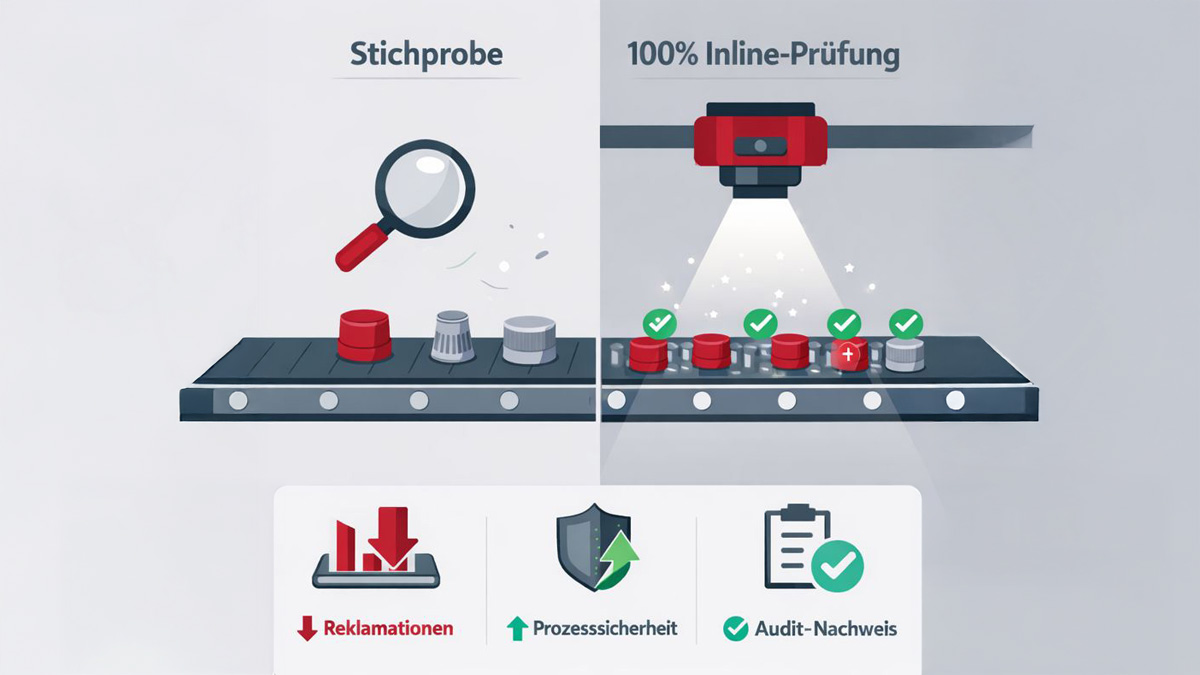

Initial situation: A medtech manufacturer only checked cleaning items such as plugs and filters on a random basis. This meant that tiny particles and fibres sometimes went undetected – with the associated risk of complaints, audits and unnecessary costs.

Our approach:

- Development of an inline-capable inspection system for 100% control

- Optimised lighting to reliably reveal even very fine particles

- Documentation of inspection results for validation and verification requirements

The result:

- Significantly reduced complaints

- Higher process reliability

- Traceable database for customer audits

- Lower quality costs due to fewer complaints, rework and rejects – and thus higher profitability

This turns ‘we check at random’ into ‘we know exactly what leaves the line’.

Contact us for your inline inspection!