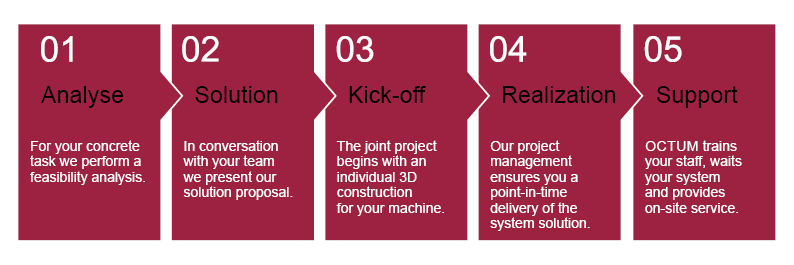

You will receive your industrial machine vision solution exactly according to your requirements and in compliance with current development standards. We go to the limits of what is technically feasible. In-house development and production enables us to react quickly to your requirements. You save time and money with our all-round service: electromechanical manufacturing, project management, our own documentation department, 3D design, E-plan, customer training, commissioning and service worldwide. You also get individual components in hard- and software which cannot be bought in addition like:

- Special lighting

- 3D sensors with Scheimpflug adapter and telecentric optics

- Sensor heads for flared cap or plug seat Check

- Mechanics for camera and lighting mounting

- Protective housing

- Software modules for 3D surface inspection, 3D OCR, assembly inspection etc.

- HMI system software for intelligent cameras In-Sight

- Customer-specific software connections to internal processes etc.

A special service that distinguishes us is the customized 3D construction drawing. This makes the relationship to the actual machine conditions at the installation site comprehensible and illustrative for both parties at a very early stage of the project. This way it can be clearly determined how well the machine vision system fits into the machine, while making optimum use of the installation situation. The entire software development at OCTUM is done according to Scrum methods and ensures transparent, traceable development processes and ultimately validatable and validated system software.

Use the full potential of your system - We offer practical training for operators and setters, tailored to your system solution. Preventive maintenance measures increase the availability of the systems and reduce potential downtime costs. Remote maintenance is an economical alternative to on-site deployment. OCTUM also offers secure tunnel solutions which are based on a higher acceptance of the customers EDP.

We only promise what we can keep and we keep our promises.