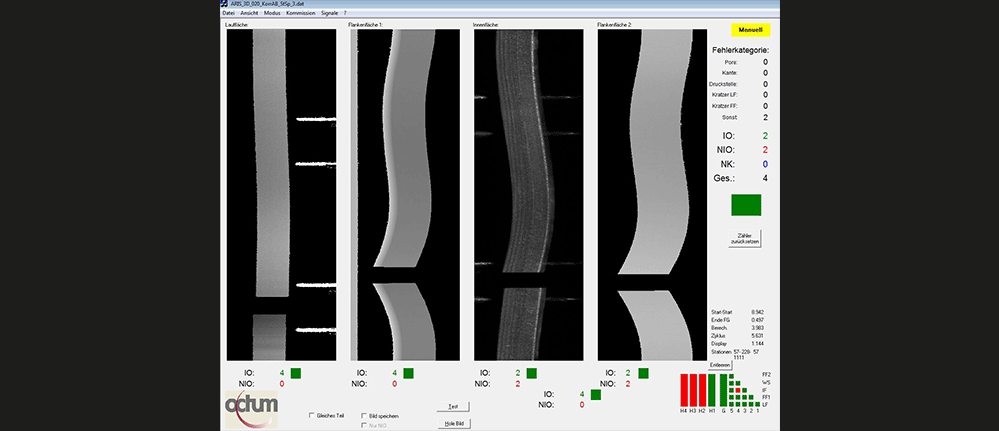

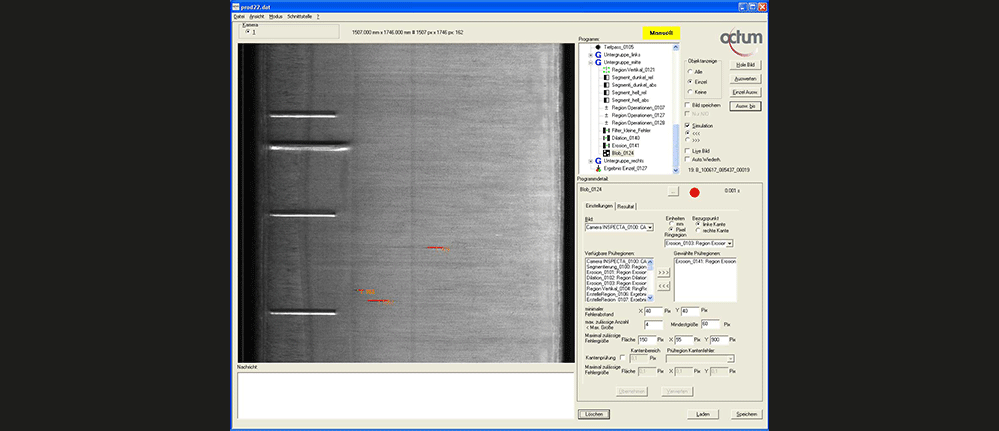

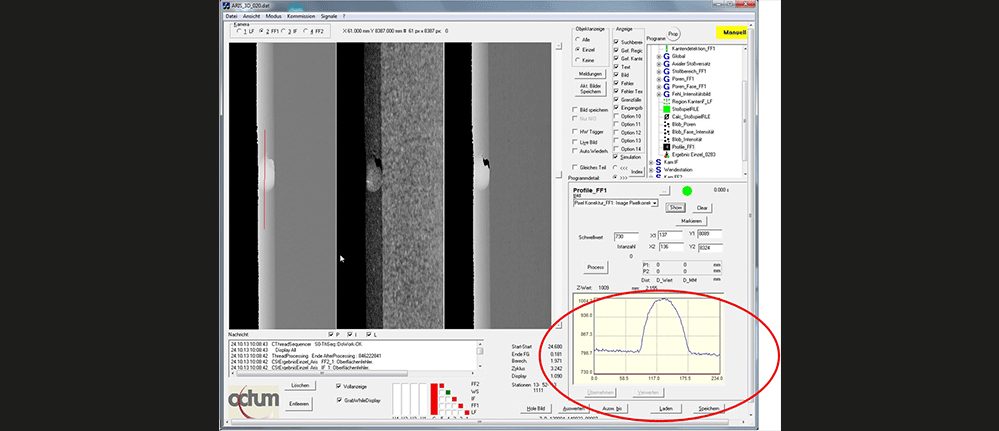

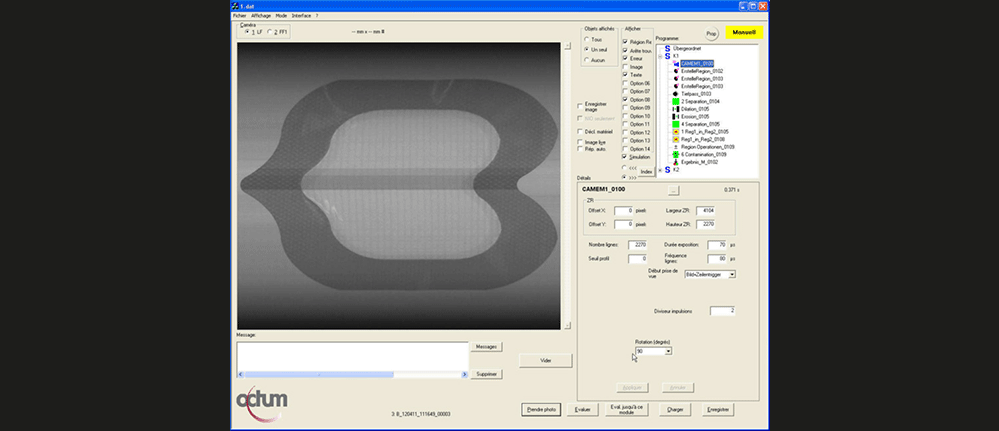

During the automatic surface inspection of metallic parts, contamination, processing traces, detergent residues and permissible material discoloration often lead to increased pseudo rejects when using 2D inspection methods. Surface defects on matt black coated metal parts cannot be inspected with 2D methods. For this task class OCTUM uses inline 3D surface inspection systems based on laser triangulation. If no suitable 3D sensors are available for the specific task, we develop and manufacture them ourselves. Also the system software for surface inspection, especially in the 3D area, is continuously developed with practical tools, e.g. for vibration compensation or phase compensation of the 3D planes as well as 3D defect classification. The system solutions for surface inspection can be parameterized so that adjustments of the defect criteria, inspection severities, inspection regions, defect classification etc. can be carried out by the customer. Likewise, new inspection programs for new part geometries can be created in-house after appropriate training.

The automatic surface inspection finds every defect.

The 2D or 3D surface inspection systems are each designed for the specific task for any geometries and materials in order to reliably control material or production-related defects. Depending on the task and cycle time, both stationary and robot-guided cameras can be used. Typical detectable defects for individual parts are e.g. dents, impact marks, blowholes, chipping, pimples, discoloration, rust, scratches, grooves, grinding errors, etc.

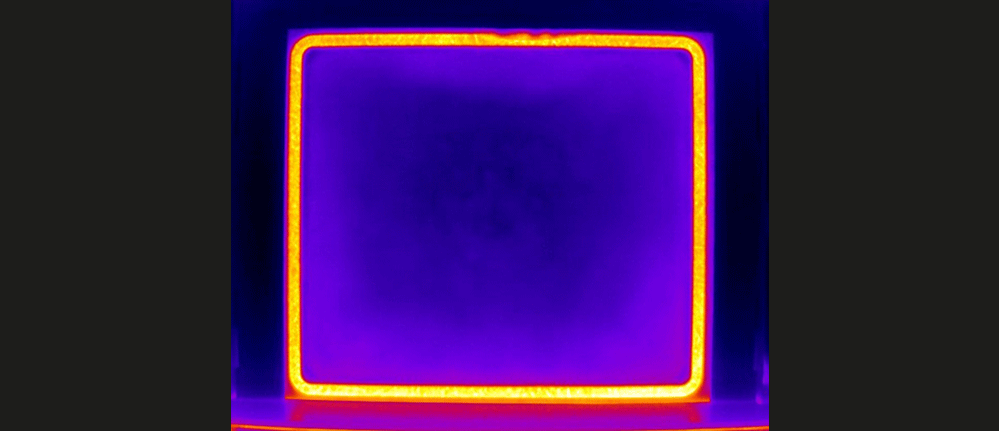

Our surface inspection systems for pharmaceutical applications are mainly equipped with line scan cameras in order to reliably find defects in technical textiles or pharmaceutical products even at high web speeds. For special tasks in the field of seal inspection, thermographic cameras can be used in combination with cameras that work in the visible range.