Optical assembly inspection – 100% quality, 0 complaints.

High-quality and complex components such as chainsaws, gearboxes, engines, automotive ZSB, medical devices etc. are produced on a single line in an ever increasing number of variants. This requires flexible solutions for the automatic final or intermediate inspection of these components which can handle the variety of features and variants economically and, above all, can grow cost-effectively for future variants. The ideal solution for this task class are stationary or robot-guided 2D and 3D assembly inspections which offer a maximum of flexibility at a reasonable price and are future-proof.

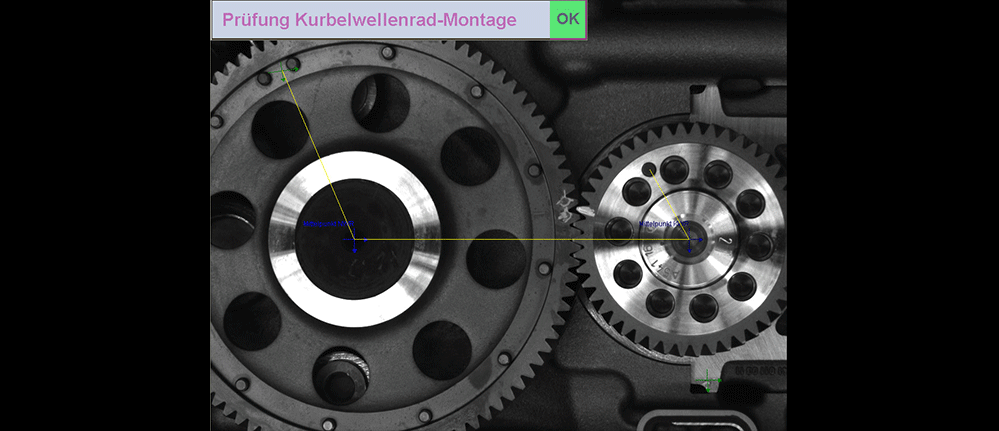

Our system software CV-Inspect offers a variety of standard machine vision functions for the task classes workpiece identification, 2D/3D measurement and inspection, feature inspection, code and character recognition, colour recognition, texture analysis etc. This means that any number of 2D or 3D features such as dimensions, contours, shape, surfaces, 1D and 2D codes and plain text can be inspected. The modular structure and simple operation of our inspection systems also enables the user to create and manage any number of types or variants of workpieces. Trained customers can, among other things, create new product variants, change the inspection programs, insert new quality criteria, adjust tolerance limits for the inspection criteria, train new patterns and contours, parameterize the assignment to the classes good, bad, rework, etc.

Extensive statistical functions facilitate the localization of weak points in production and thus enable rapid quality improvement or process optimization. The integrated logging and archiving of image data, too, guarantees complete documentation and ensures traceability.

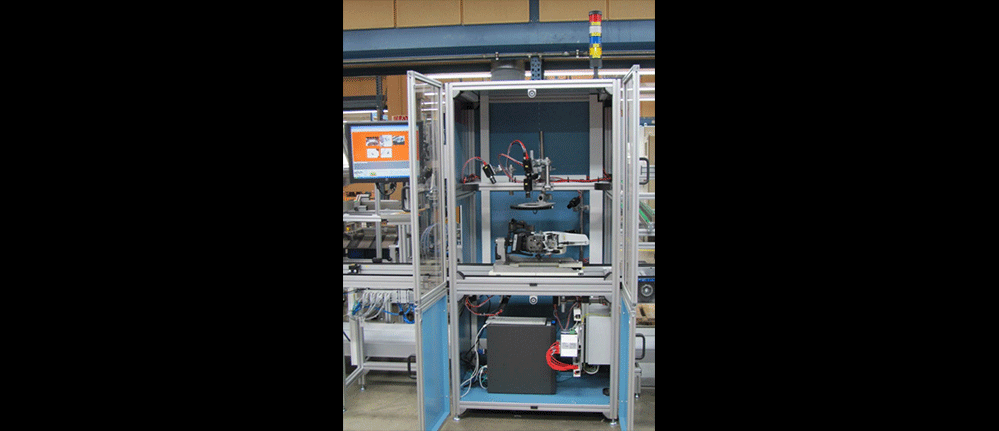

Optical assembly inspection at high throughput – first choice solution with stationary cameras.

At high cycle rates, solutions with one or more stationary cameras remain the first choice for optical assembly inspection. Specific LED illumination switched asynchronously ensures optimum contrast in clocked processes. For assembly inspection of moving parts, different coloured LED lights are usually used in flash mode to avoid mutual interference between the cameras.

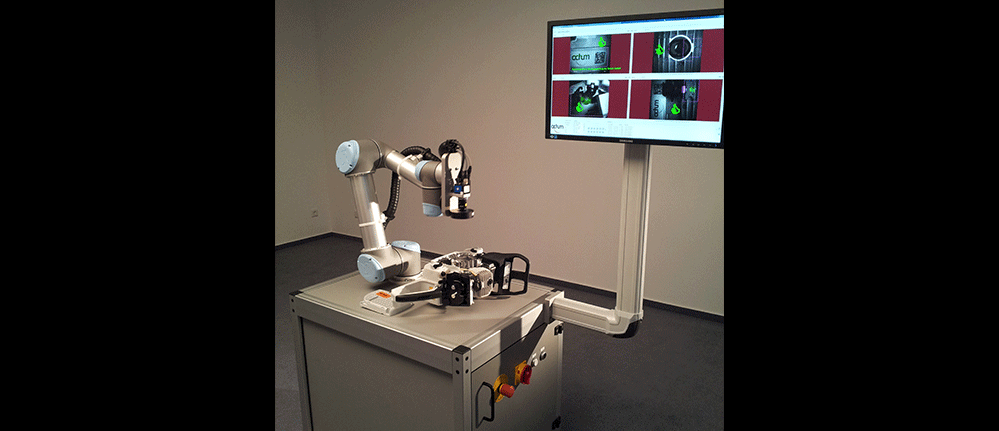

Optical assembly inspection at lower throughput – robot-guided camera flexible alternative.

The further development of the OCTUM system software CV_Inspect creates the basis for flexible robot-guided assembly inspection by implementing the logical cameras. This means that one physical camera can be used at different inspection locations with different camera parameters. The use of lightweight robots for camera guidance also makes it possible for the user to handle the robot without special robotics knowledge and complex safety precautions. A new inspection position can be easily adopted into the test sequence by simply switching the robot to zero gravity and moving it to the new inspection position. The extension with new test characteristics is done in the usual way by parameterization of the test as before. This provides an almost unlimited flexibility with undreamt-of inspection possibilities for the dynamic and economic design of production processes.