Visualization, parameterization and operation for PC-based machine vision solutions.

The CV_Inspect system software, which has already been used hundreds of times, was developed for the assembly, completeness, surface inspection and measurement of parts in the automotive, metal processing, pharmaceutical and medical technology and healthcare industries.

CV_Inspect 6.x features:

- Database based and parameterizable for simple to complex tasks

- Flexible application: measuring, testing, detecting and identifying

- Simple structured operation with comprehensive safety concept

- Wide range of practical test functions

- Flexible parameterizable results and process couplingTracing of the communication signals for fast, error-free process integration

- Extensive statistics and measured value recording in an integrated database

- Range of functions can be extended application-specific and therefore future-proof investment

- System software also applicable for GAMP projects in the pharmaceutical industry with audit trails according to 21 CFR Part 11

- User management including Active Directory connection

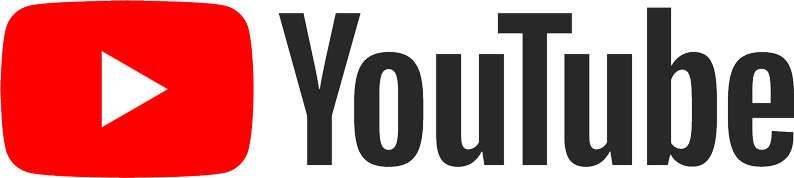

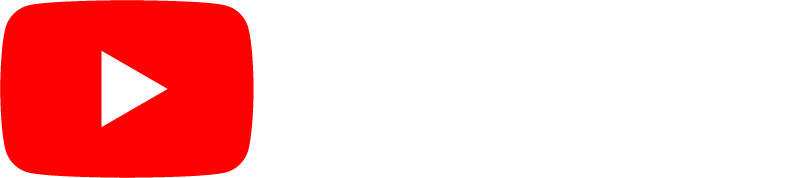

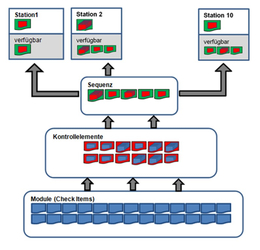

CV_Inspect is suitable for up to 10 stationary cameras with fully synchronous/asynchronous operation as well as for robot-guided cameras. Lighting and camera settings can be individually parameterised. Currently cameras from various manufacturers are supported (Cognex, Basler, Dalsa, AVT, SVS Vistek, etc.). With CV_Inspect you parameterise your machine vision application instead of programming. You have a maximum of flexibility to solve even complex problems quickly. The modular design enables customer-specific functional extensions and rapid familiarisation with operation and parameterisation. The clearly structured user interface and the operation, which is the same for each element, guarantees a high acceptance by the trained operator.

The integrated syntax check prevents errors in the structure of the test program with the exception of logical errors. The extensive range of functions offered by the Cognex Vision-Pro library as the module basis of CV_Inspect can be extended by customer-specific functions to enable it to handle even currently unsolvable tasks in the future Flexible linking of results and practical communication functions allow a wide range of integration options into the automation process via all common interfaces.

The integrated practical functions for test, statistics, storage and measurement data acquisition also provide a high level of customer benefit. Measurement data can be visualized and stored during running automatic operation without influencing it. Likewise, the visualization can be parameterized to a large extent and displayed either with individual camera images or a synthetic image of the overall view and individual test positions with respective results. The graded user access via 5 user levels ensures that every user logged in has rights for system operation according to the assigned user group.