Optical measurement – accurate to the µm, reproducible, non-contact.

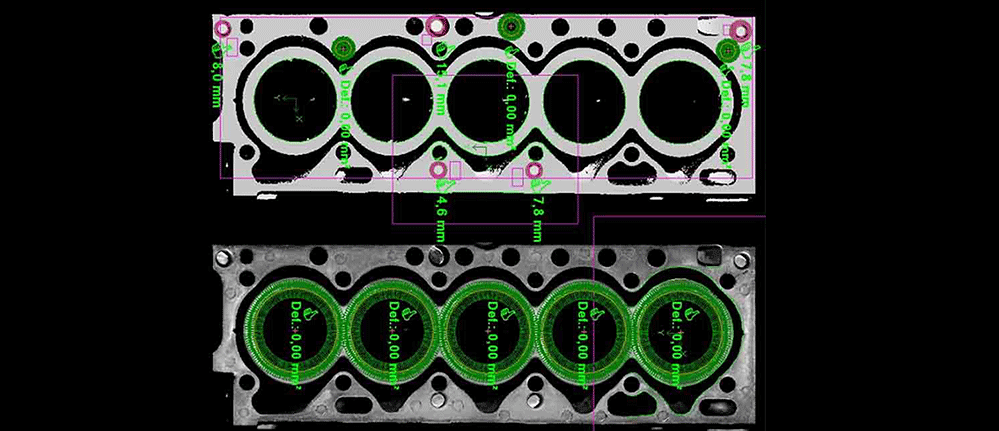

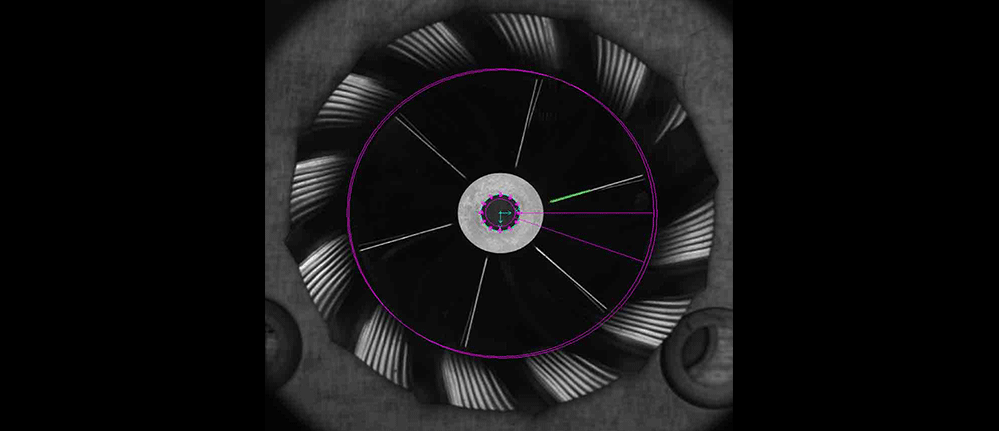

High-quality and complex components often consist of many manufactured and assembled individual components. Each individual component has to meet tight dimensional tolerances to ensure smooth and faultless functioning. Systems for precise optical 2D and 3D measurement are required to verify compliance with these tight tolerances. Depending on the process and requirements, off-line measurement for the correct adjustment of the processing machines or in-line measurement of each component or a combination of both methods can be the right solution.

Optical measurement in 2D is designed for specific applications and usually includes bi-telecentric optics with specific incident light or telecentric transmitted light illumination. In addition to careful project planning and selection of the right components, the mechanical design with the most precise adjustments of the components is also important. For this purpose, we supply field-proven mechanics and wobble units from our own production. Together with the mature system software, we achieve repeatabilities of up to 2µm in our projects according to method 1.

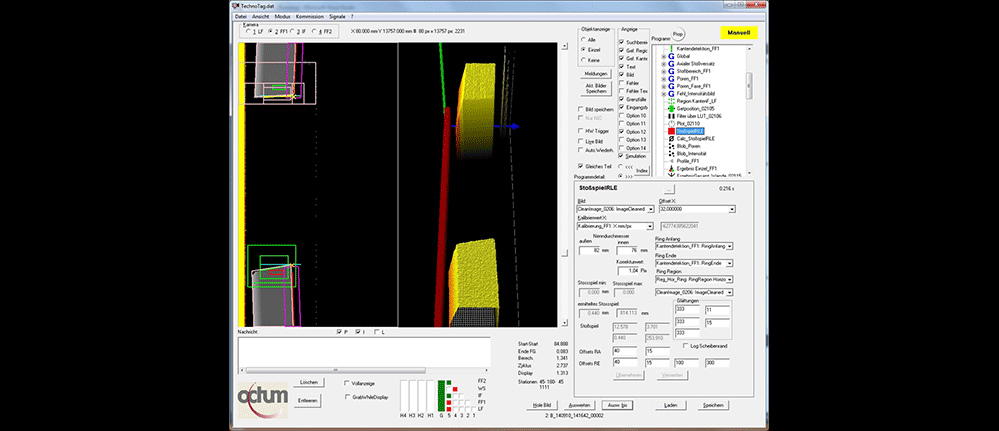

The image processing solutions for 3D optical measurement usually include triangulation cameras or stereo cameras. Careful project planning is decisive for the achievable measurement accuracies. We realize 3D optical measuring exclusively with PC based systems.