Reading of codes & characters - ensures traceability.

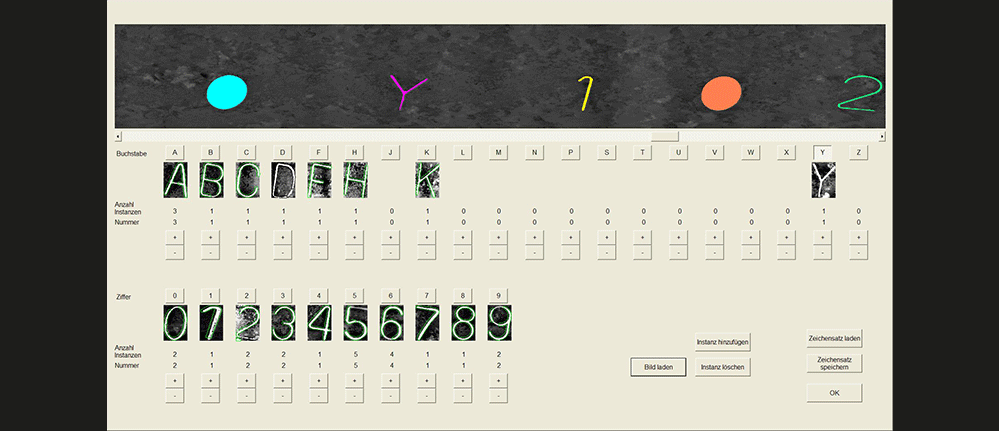

Machine Vision systems for reading and verifying codes and characters enable automatic material flow control and traceability of your products. Standard 1D and 2D codes are also reliably and quickly recognised as DPM codes, such as the Data Matrix code, under difficult contrast conditions. Reading and verification (OCR and OCV), especially with non-standard character sets such as embossed characters, may require manual teach-in of the character set. The recognition software works in gray or 3D image and classifies the characters according to taught-in character patterns in the production cycle. In case of difficult contrast conditions or strongly fluctuating characters and codes, several characters of one class can be learned. The user can learn new characters himself via the simple user interface - standard interfaces are available.

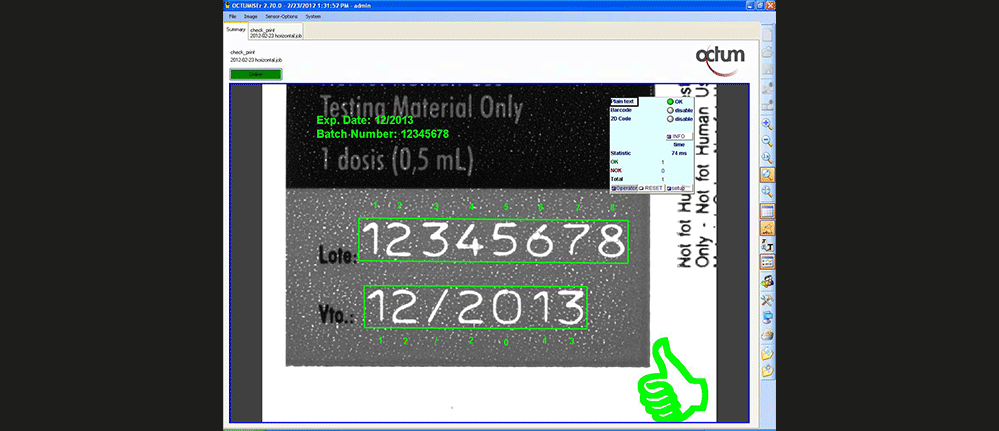

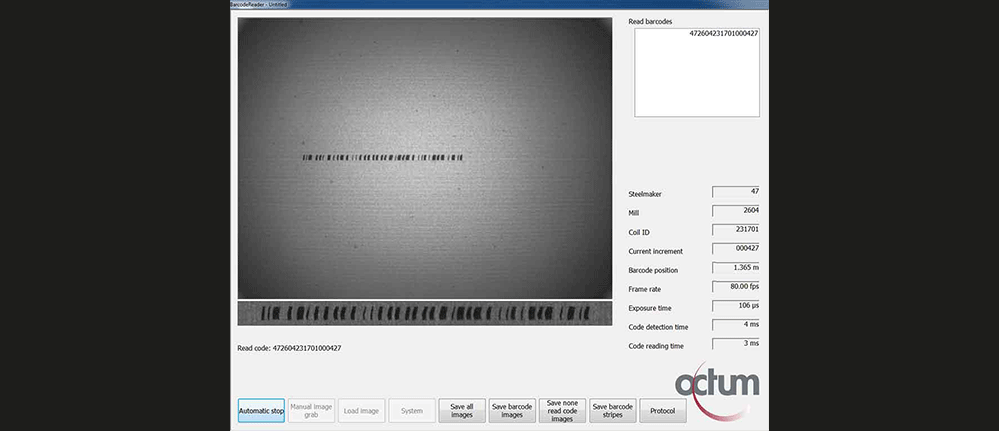

2D reading of codes and characters – reliable even at high speeds.

For simple to complex tasks in 2D reading of codes and characters, we usually use handheld or stationary ID systems from our partner Cognex. Even non-visible (e.g. UV codes) and difficult to contrast codes can be read reliably with a specific optical design. Especially in the pharmaceutical industry, combinations of multi-line codes, plain writing and printed symbols are reliably identified with OCTUM system solutions. The reading of 1D codes on steel coils at speeds of up to 300m/min for track and trace tasks in steel production and processing, we have implemented with PC based systems with the highest recognition rate. Our PC-based OCR systems read barely visible plain text lasered onto blanks at speeds of up to 180m/min. Our OCR systems can cope with large fluctuations in size, position and arrangement of characters, e.g. on compressor wheels.

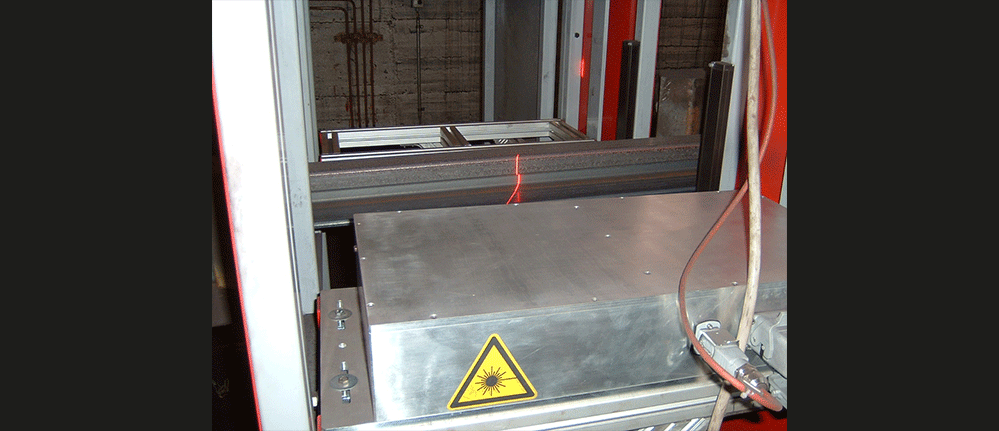

3D reading of codes and characters – reliable recognition even at low character depth.

The reading of 3D codes and characters for safety-relevant markings is done by our PC-based systems with 3D cameras based on laser triangulation. At high speeds we use permanently mounted 3D cameras. For embossed characters on high-quality castings with several embossing surfaces, robot-guided 3D cameras can also be an economical alternative. Our 3D OCR systems read e.g. also embossed characters with low embossing depth on railway rails at speeds up to 1.5m/s and rail lengths up to 120m. We achieve scan rates of up to 15kHz and very high reading rates even with scaled surfaces.