Thermo-molded products such as drink beakers and storage beakers with and without lids are a frequent part of daily life especially in the food industry. Whether 20 g portion packs or a 500 g quark pack. There is hardly any alternative to the thermo-molded plastic pack. The dimensional stability of the beakers and lids is an important factor here for the stackability and tightness of the lid seal. The dimensional stability also plays a role in the customer-specific optimization of the force with which the lid can be fit or removed. The accurate measurement of the beakers and lids should be used to quickly optimize the thermo-molds (i.e. the tools for thermo-molding) when running in a new product and to assure the quality of the thermo-molds and thus the quality of the products. The wide variety of round drinks beakers up to rectangular lids with a pull tab need to be measured precisely without great effort.

Machine vision solution from OCTUM for precise measurement of plastic cups and lids.

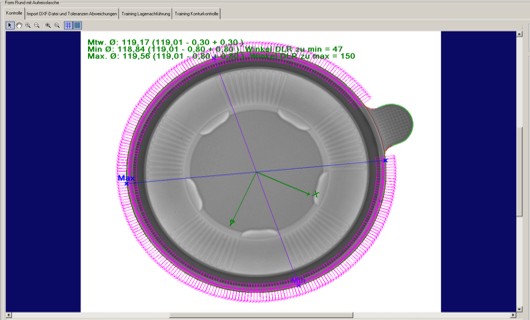

In the conception of the optical measuring system, the part variety and the demand for as easy as possible handling of the measuring system without the need for mechanical adjustment of the optical components and without programming or parameterization of the measuring task was a challenge. The cups and lids can be transparent or white. The permissible cup or lid height is between 1 mm and 185 mm. The cups can be measured standing on the bottom or top down. In order to meet these demands, an optical measuring system with blue back-lighting, high resolution GigE camera and bi-telecentric measuring lens with 245 mm opening diameter and 260 mm telecentric range in a stable mechanical structure was developed. The simple operation of the system is ensured on the software side by the OCTUM system software CV-Inspect. CV-Inspect also uses DXF files directly from the product manufacturer's CAD system among other things as a basis for training and measuring. The inspection regions for the optical measurement are generated automatically from these DXF files. After inserting the cups or lids manually, these are then measured semi-automatically for diameter, roundness and other shape-specific dimensions. The measuring accuracy is +/- 50µm. The measured values are visualized to enable direct conclusions to be drawn for optimization of a thermo-mold and recorded statistically as a proof of quality for the customer. The measuring system was installed and commissioned at the product manufacturer's in two days. The system was ready to measure after calibrating the system and loading the CAD data.

Customer benefits

The objective and fast measurement of the products immediately supplies data for the process optimization when running in new products. The continuous inspection of the products ensure long-term consistent quality of mass products for daily use.&nb