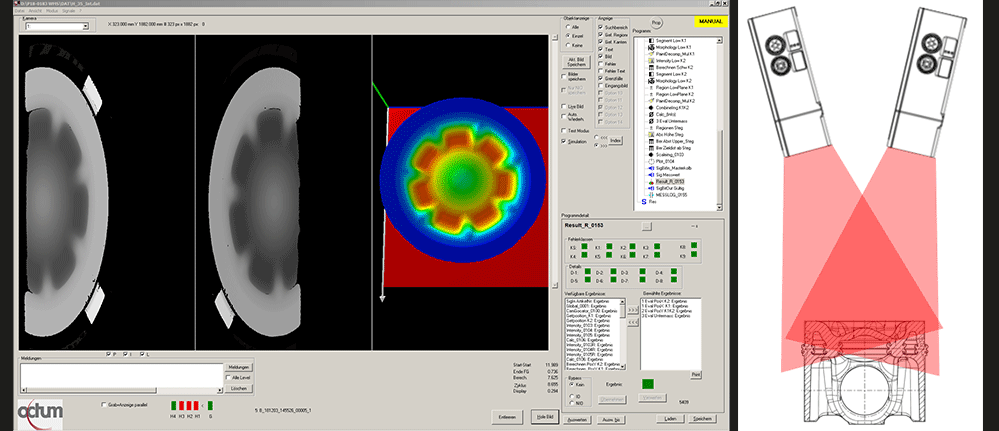

3D volume measurement on vehicle pistons.

In order to achieve the target volume as accurately as possible after piston machining, the piston blanks are measured three-dimensionally before machining. Parameters for the control of the machining centers are derived from the measured data so that a desired target volume is reliably achieved after machining. Piston blanks without this target volume are not machined.

In order to achieve this efficiency, the piston blanks are measured with two 3D sensors, whose images are stitched together in 3D to achieve a complete image of the combustion chamber without shading areas. Based on this 3D data the actual volume and height of the piston is measured and the machining parameters are determined to achieve a target volume and height. These parameters are transferred to the control system of the machining center and thus guarantee the production of an IO piston according to specification.

The two 3D sensors are individually calibrated. The position of the sensors in relation to each other in space is also calibrated by means of calibration bodies in order to enable an exact composition of the 3D image data. To ensure the correct 3D measurement process it is necessary to provide an external reference in the form of a measured master piston in a separate station. The repeatability for height measurements is in the range of 10µm and for volume measurements in the range of 0.02mm³. The measuring process and the result transfer to the PLC are handled via Profinet interfaces. The system is parameterizable and can be extended to other suitable products as well as adapted for other machining centers.